Solar Technology

Calculations

The Ultrasonic cleaner is to be powered using a combination of a rechargeable battery and a solar panel. Our initial aim was to rely just on energy produced from the solar panel, however, due to changes in weather, the efficiency of the panel will not be constant, therefore will not be a reliable power supply. This, coupled with the fact that you will not be able to use the cleaner at night meant that we had to provide an alternative power supply in the form of a rechargeable battery.

There are two main types of solar panels, mono-crystalline and poly-crystalline. Poly-crystalline panels have multiple cells cast into an ingot. This is a cheap process, however it leads to a less uniform structure which reduces efficiency. To reduce this inefficiency the crystals are made large and the ingots are cast in a square shape. This allows for the ingots to tessellate more accurately, reducing areas of inactiveness. Mono-crystalline panels have a single crystalline lattice structure with very few defects. These are expensive to produce, however typically have 2% greater efficiency above poly-crystalline panels. The crystals tend to be cylindrical, so when cut and mounted there are inactive areas between slices [10].

The direction that the panel is facing is vital. As the direction of the sun is continually changing throughout the day it is important for the panel to be facing the correct position at all times. If this is not done, only a proportion of the irradiance from the sun will be shining on the panel. For fixed solar panels this requires a complex mounting arrangement and algorithms to automate the movement in the correct angle. We did not want anything this complex for our product; as if it breaks it will be hard to repair. So our proposed product design (see Figure 10) has a mechanical pivot, which can be manually adjusted to the correct angle of the sun. This allows for continual adjusting and simple repair.

Ideally we would use a microcontroller that actively selects which source to use, solar or battery. However in order to get a solar panel to supply enough power for the cleaning would require a very large panel. Therefore we had to settle for a smaller panel, which is only used for charging the battery.

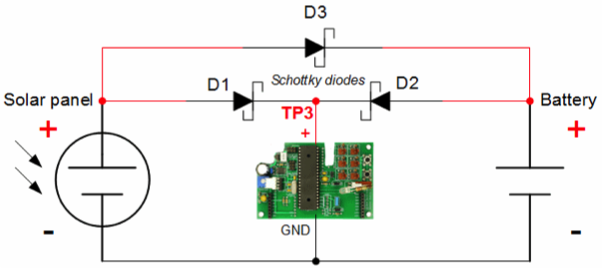

The solar panel is connected to the rechargeable battery through a diode, see Figure 3. A blocking diode is required as it stops the solar panel from drawing current from the battery in low light conditions [11]. The solar panel will keep recharging until the voltage on the battery is equal to that of the solar panel. Therefore it is important for the voltage of the panel and the battery to match, preventing under or over-charging of the battery.

There are two main types of rechargeable batteries, nickel-metal hydrate (NiMH) and lithium-ion. NiMH batteries are the most commonly used types of rechargeable batteries [21]. The lithium-ion batteries have the highest energy to mass ratios for all rechargeable batteries, and also have a very slow loss of charge when not in use. For these reasons we will use the lithium-ion battery as it allows us to save space in our design.

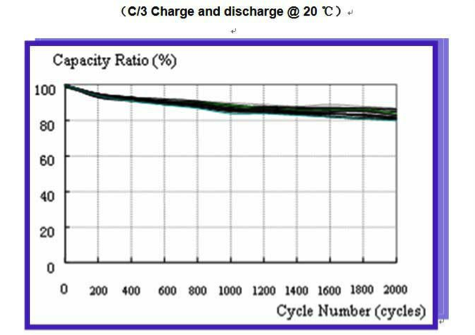

All batteries have a life cycle, whereby the capacity of the battery reduces as the number of recharges increases. Figure 2 illustrates a typical rechargeable battery, as you can see, after 2000 recharges the capacity has reduced to nearly 80% of original capacity. Because of this, we may be required to replace batteries after a certain period.

Battery capacity is measured in Amp Hours (e.g. 17AH). To convert this to Watt Hours we multiply the AH figure by the battery voltage, in our case 12V. For a 17AH, 12V battery the Watt Hours figure is 17 x 12 = 204WH. This means the battery could supply 204W for 1 hour, or 102W for 2 hours i.e. the more energy we take, the faster the battery discharges. The power consumption of the machine is given in Watts, to calculate the energy we will use over time we multiply the power consumption by the hours of use, for 50W on for 2 hours, its 100WH.

The power generation rating of a Solar panel is also given in Watts (50W in our case). To calculate the energy it can supply to the battery, we multiply Watts by the hours exposed to sunshine, and multiply the result by 0.85 (this factor allows for natural system losses). For the Solar 50W panel in 4 hours* of sunshine, 50 x 4 x 0.85 = 170WH. This is the amount of energy the Solar panel can supply to the battery.

Therefore we will choose a 12V 20Ah lithium-ion rechargeable battery. It can store 240WH, which means the battery can supply 240W for 1 hour, or 50W for 4.8 hours. A sample solar panel and battery connection is shown in Figure 3.

Figure 2: Battery capacity at different number of cycles [19]

Figure 3: Solar panel and battery connection [12]

Regions

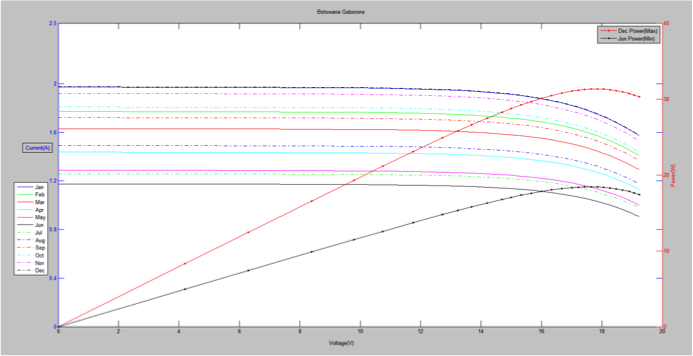

We looked into solar irradiance data of a few countries around the world with high prevalence in HIV/AIDS infection through injection. Figure 4 shows solar irradiance data of Gaborone, Botswana. Graphs of Ukraine, Myanmar and Mauritius can be found in Appendix A (Diagram 5, 6, 7). In Gaborone, the lowest solar irradiance power achievable is around 18 W for a typical June and the highest at around 32 W in a typical December.

Figure 4: Solar irradiance data (monthly average over 22 years) [12] of Gaborone, Botswana (drawn by MatLab)