Cathode ray tubes have a long illustrious history. Their invention dates back to 1897, they have been found most commonly in the television since the late 1930's.

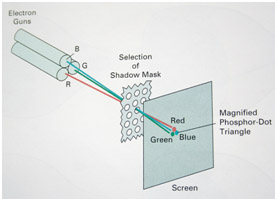

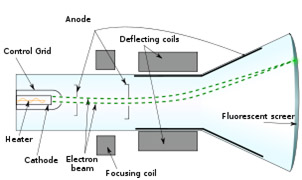

A simple CRT mainly consists of an electron gun (include an accelerating electric field), a deflection coils, a shadow mask and a fluorescent screen (picture on the right). It is used to create images, widely applied on display devices such as televisions, oscilloscopes and computer monitors. However they have gradually been replaced by liquid crystal (LCD) and plasma displays in many applications.

An electric field is placed in front of the electron gun and is used to accelerate the electrons emitted by the electron gun. A magnetic field perpendicular to the E field is imposed by deflecting coils. It can control the path of the electrons by adjusting the strength of the magnetic field. The image will appear when electrons hit the phosphor screen.

The demise of CRT in the present day commercial sector(televisions etc) is interesting in that CRT based technology remains superior in several ways to competitors such as the LCD. We can look at some comparisons to justify this but also look at the reasons for which it has been replaced.

By 2008, although CRT TV and computer displays were still used in developing countries, they had almost disappeared in the developed world. The liquid crystal displays have become more and more popular in recent years.

Let’s compare the performance of them in different aspects:

- Resolution: A colour CRT display has three electron guns and three different phosphors on the screen which emit red, blue and green light respectively. A metal plate with tiny holes is placed in front of the fluorescent screen to ensure that the electrons from each gun strike the corresponding monochromic phosphor. This metal plate is known as shadow mask. The distance between holes on the shadow mask is called dot pitch, which determines the maximum resolution of a CRT display. A CRT can display an image with any resolution lower than the maximum dot pitch defined resolution, as the electron gun can flexibly make adjustment.

For LCDs, the pixels have a layer of liquid crystals aligned between two electrodes and two polarising filters that are perpendicular to each other. Under a control signal, the liquid crystal molecules twist themselves (in twisted nematic type panels, which dominate the consumer market today) to reduce the rotation of the polarization of the incident light in different levels to pass light through the second polarizing filter. Hence the image appears on the screen. The imaging principle of LCD determines that for a fixed size of screen, the pixel arrangement is only suitable for image (signal) with a particular resolution (native resolution).

For LCDs, the pixels have a layer of liquid crystals aligned between two electrodes and two polarising filters that are perpendicular to each other. Under a control signal, the liquid crystal molecules twist themselves (in twisted nematic type panels, which dominate the consumer market today) to reduce the rotation of the polarization of the incident light in different levels to pass light through the second polarizing filter. Hence the image appears on the screen. The imaging principle of LCD determines that for a fixed size of screen, the pixel arrangement is only suitable for image (signal) with a particular resolution (native resolution).

- Colour Reproduction: CRT's naturally have very good colour reproduction compared to LCDs. This made them first choice for professionals who deal with colours in graphics or editing where colour reproduction is paramount. LCD technology has greatly alleviated the difference however.

- Volume: LCDs have absolute advantage in terms of volume. The thickness of an LCD will only be a few centimetres no matter how big the screen is. But for CRTs, the larger the screen, the greater the volume will be occupied because of its imaging principle requiring the projection of the electron beam. Size commercially is probably the most important of all the factors contributing LCD dominance in present years. On top of this, LCD have improved so much and costs have reduced so quickly that demand has increased incredibly fast.

While gradually being superseded by LCD technology due to practicality issues such as size, CRT has held some distinct advantages, which for some time, gave scope for further evolutions of the technology.

The most notable development was in the early 2000’s where various companies came out with competing technologies to improve upon LCD contrast ratio. Emerging technologies at the time included SED (surface conduction electron-emitter display), FED (field emission display, related to SED) and OLED (Organic Light Emitting Diodes) variants.

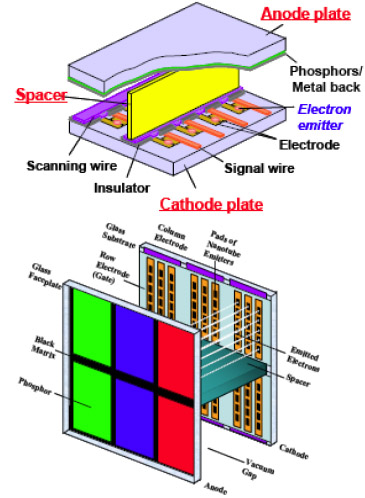

SED based technology use large grids of nano-emitters as opposed to a single electron gun which is typical of CRT displays. This allows for the depth of the SED display to be similar to that of an LCD and each pixel may emit its own light allowing for much greater contrast ratios not achievable by conventional LCDs.

FEDs are similar but use different emitters of bundled carbon nanotubes, this allows redundancy for defects due to the number of nanotubes in each bundle. Theoretically this would improve yields on a commercial manufacturing basis. SED are considered a more practical technology to FED as the technology allows greater gray scale uniformity.

As of today, both technologies have experienced manufacturing difficulties and failed to reach a commercially viable state before OLED became a natural successor. OLEDs now has most research and development from technology companies, they are able to operate without a backlight and can be made incredibly thin. They do however, suffer from degenerative effects thus have comparatively short life spans. Main developers of SED related technology such as Canon have stated that it has not disappeared entirely and may make its way into professional applications in the future.

The rapid fall in LCD cost has also made SED commercially difficult.SED appears to be a case in which a good technology has not taken hold due to various external reasons, marking a major loss in the commercial future of thermionic technology.

Further Reading/ References:

1. Fink, R.L. & co., “Technical Comparison between SED and FED”. http://www.appliednanotech.net/tech/pdfs/fed_sed.pdf

2. http://en.wikipedia.org/wiki/Horizontal_scan_rate

3. http://www.reuters.com/article/idUKT36435820090824